When it comes to product development, understanding how long a product can reliably last in the hands of its users is crucial. But how do you ensure durability without waiting years for results?

That’s where product lifecycle testing comes into play.

What Is Product Lifecycle Testing?

Lifecycle testing simulates the long-term use of a product, providing valuable insights into its durability, reliability, and overall performance–without the need for real-time, extended observation. Through a variety of testing methods, product developers can stress-test products under conditions that mimic real-world usage. Whether it’s a simple household gadget or a complex piece of industrial equipment, every product benefits from testing to guarantee it will meet user expectations over time.

Why Do Products Need Lifecycle Testing?

The importance of lifecycle testing can’t be overstated. Here are a few reasons why companies across all industries deem it essential.

- Quality Assurance: A reliable product translates into customer satisfaction and brand loyalty. Testing helps ensure that the quality lives up to consumers’ expectations, whether it’s longevity, performance, aesthetics or safety.

- Industry Standards and Certifications: Many products must meet stringent standards to be sold in certain markets. Testing helps ensure compliance with necessary certifications.

- Early Defect Detection: Components or subassemblies identified as high-risk can be tested early in the development process and can save time and resources.

- Consumer Confidence: A well-tested product gives consumers peace of mind, knowing that it will operate predictably and reliably for a given length of time.

- Expanded Market Opportunities: Passing lifecycle tests may reveal that your product is suited for additional industries or uses you hadn’t initially considered.

- Return on Investment: Before committing to full-scale production with a new manufacturer or method, lifecycle testing provides crucial data to assess if a production change is worth the risk.

- Safety and Ethics: Ensuring that products are safe for consumers is non-negotiable. Defective products can lead to lawsuits, recalls, or worse, endanger users.

Best Practices for Product Testing

It’s not enough to simply run tests—proper testing requires strategy, careful planning, and execution. Here are a few best practices to consider:

- Isolate the Component: When testing a product, sometimes it’s helpful to focus on isolating the specific part or assembly under evaluation. This allows for more accurate and sometimes more efficient testing of that component’s reliability.

- Replicate Real-world Conditions: Ensure that your testing materials and processes mimic the actual conditions your product will face. For example, if the product will be used outdoors, consider testing for rain, humidity, wind and dust resistance, temperature fluctuations, or UV exposure. Sensors that measure temperature, moisture, or sunlight exposure can help to measure and output objective data about real-world conditions. Will it be subjected to rain, salt-water spray, corrosive cleaners or blowing sand or debris? Controlled testing can be done to apply and monitor the appropriate substances.

- Monitor for Failures: Identify any points of failure during testing and document them immediately. Early detection of weaknesses can save significant time and money in the long run.

- Simulate Realistic Usage Patterns: Understand how the product will be used. Will it operate continuously or intermittently? Will it face heavy or light loads? Does the design need to withstand excessive vibrations during transportation or function reliably in various orientations? Shaker tables, accelerometers and gyroscopes can be used to record the movement during testing. Tailor the test cycles accordingly. If you’re unsure about what usage patterns will look like, it may be a good idea to consider evaluating your product with design thinking in mind as a prerequisite for lifecycle testing.

- Interpret the Results Accurately:It’s critical to correctly understand what your testing data reveals. Poor analysis could lead to incorrect conclusions about your product’s reliability.

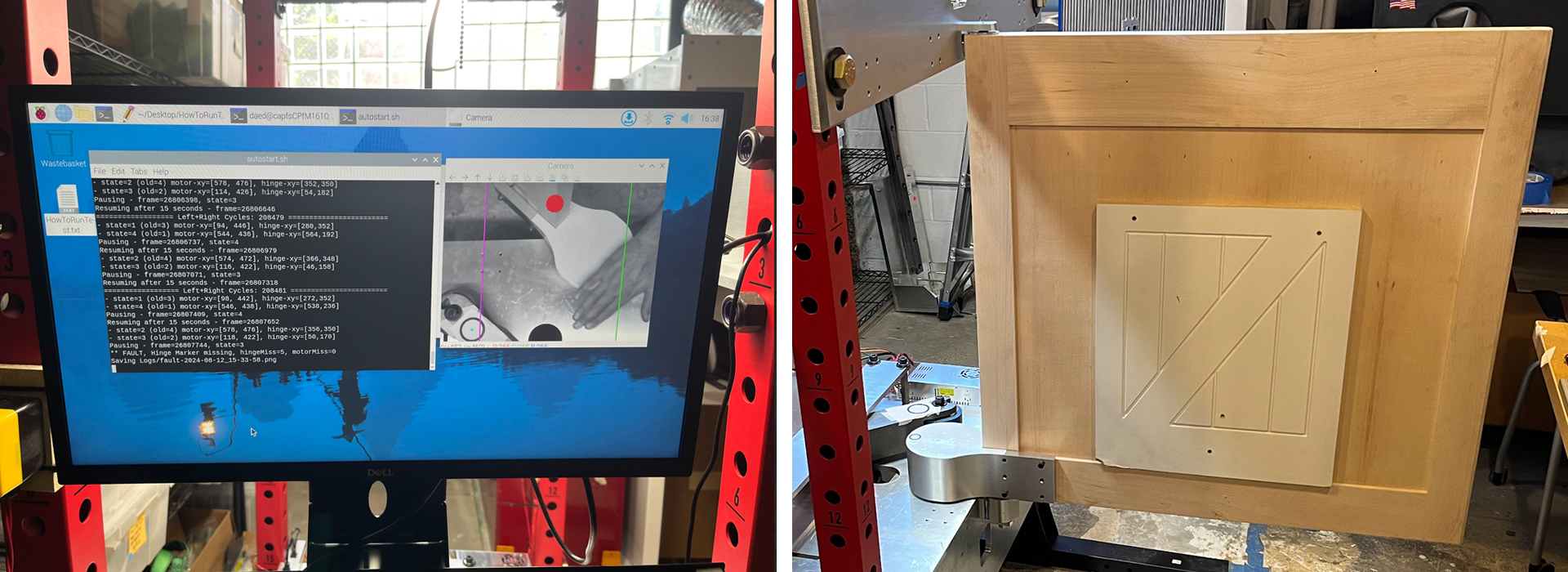

- Expensive Isn’t Always Better: Contrary to popular belief, the most expensive testing equipment isn’t always the most reliable. Sometimes, a simpler, custom-built rig, designed specifically for your product, can yield more dependable results. This is where working with an experienced engineering team can make a world of difference, helping you create a custom test environment that provides accurate data without breaking the bank.

Ensure Your Product will Stand the Test of Time

In the realm of product testing, it’s crucial to assess and test how a product performs under real-life conditions. This involves evaluating how well the product functions in common user usage patterns and environments, ensuring that it meets practical needs efficiently.

Reliability is another key aspect, focusing on the consistency of performance over time. A reliable product delivers dependable results and maintains quality without frequent failures or need for repairs. Testing for reliability often includes stress tests and long-term usage simulations to identify potential points of failure.

Lastly, longevity examines how well a product withstands wear and tear over its expected lifespan. This involves testing materials and components for durability and resistance to environmental factors such as temperature changes, humidity, and physical impacts. Ensuring longevity is essential for user satisfaction and cost-effectiveness, as it minimizes the need for replacements or extensive maintenance.

Daedalus has collaborated with companies across industries to test their products for performance and reliability. If you’re looking for a firm who can research, design, and engineer your product to make sure it stands up to the test, Daedalus can help. Learn more about our services, or reach out today.