Daedalus recently acquired a new Stratasys J850 Pro 3D printer that dramatically expands our 3D print capabilities.

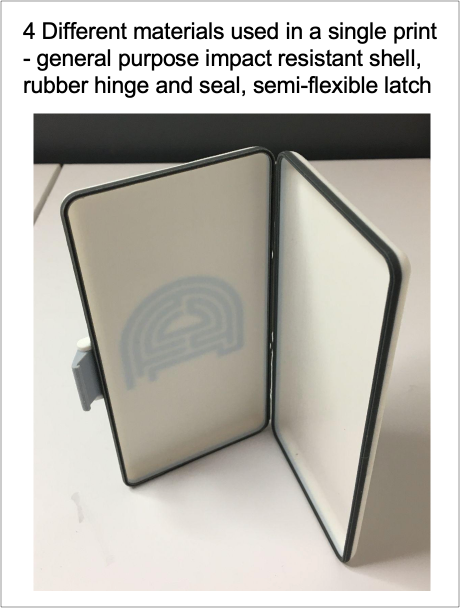

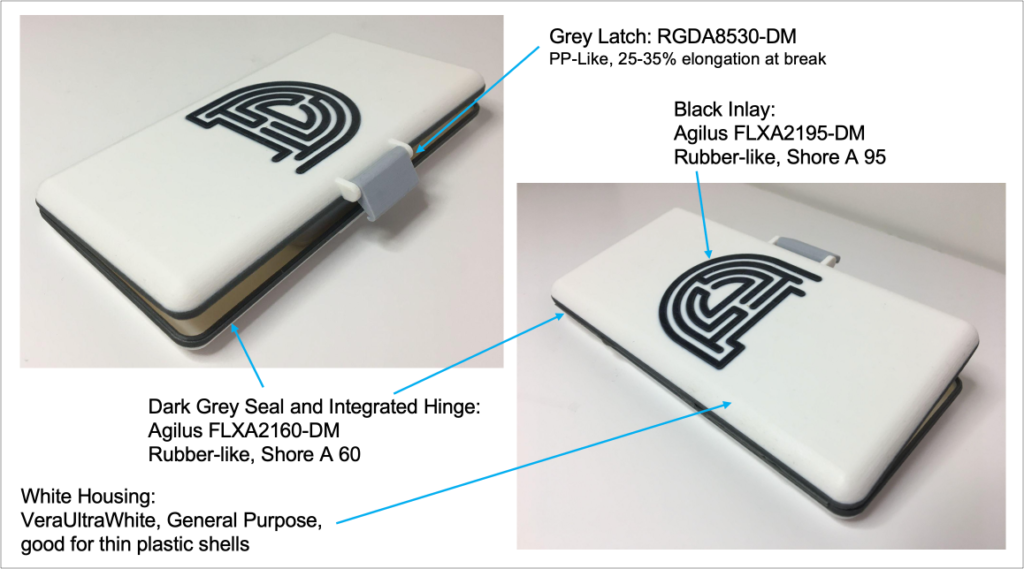

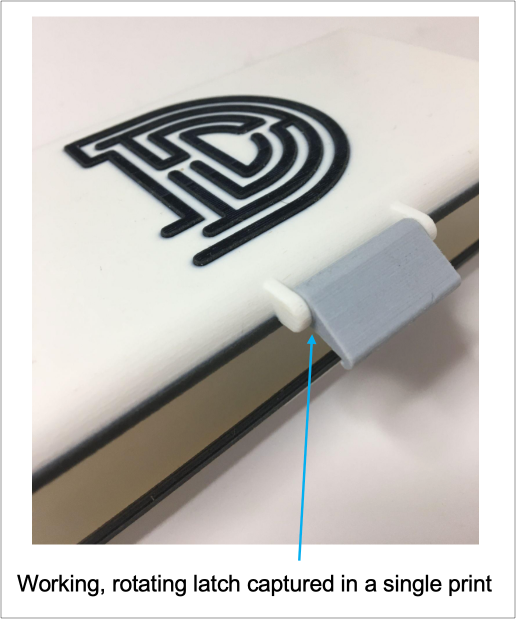

Our new printer is capable of printing up to seven (7) different materials in a single print run. This means that we can now print over-molded parts, which consist of a soft, rubbery, textured material over a harder substrate, and living hinges, like the hinge you might find on a ketchup bottle top. We can also print integrated flexible spring features for functional one-piece designs.

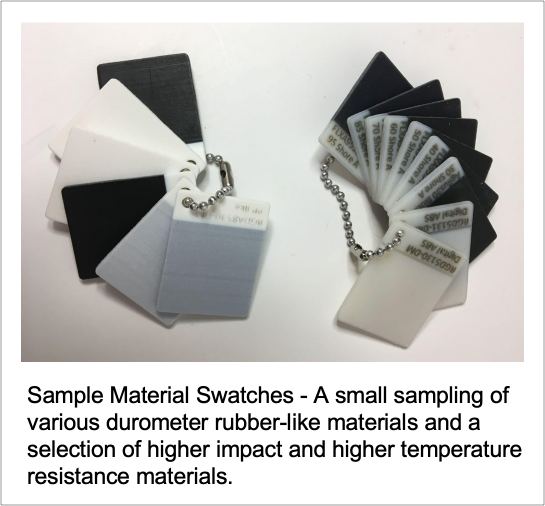

With the Stratasys J850 Pro, we can now fine-tune the hardness, opacity, and physical material properties of our 3D prints, allowing us to better simulate the properties of engineering materials, like polypropylene. This produces better prototypes that are more accurate to the final design materials.

We can also create highly functional engineering prototypes using Digital ABS Plus, a heat-resistant 3D printing material designed to simulate the more durable plastics seen in larger production runs. And by using a lower-strength low-cost material called Draft Grey, we can also print at much higher speeds, allowing us to more quickly print early, lower-fidelity prototypes.

Our new printer is capable of producing prints up to 19.3 x 15.35 x 7.9 in. And because it interfaces directly with our CAD software, we save the time we used to spend exporting generic 3D files. We have also retained our FDM and SLA printers, which we use for special material properties and to increase our overall capacity.

Below are images of a 3D print that captures many of these capabilities.

We’re excited to put our new 3D printer to the test and see what sorts of exciting new prototypes we can create from scratch in our workshop. Next time you’re visiting the office, stop by our workshop to check it out!